Asbestos on the Railroad

ASBESTOS ON THE RAILROAD

What to know:

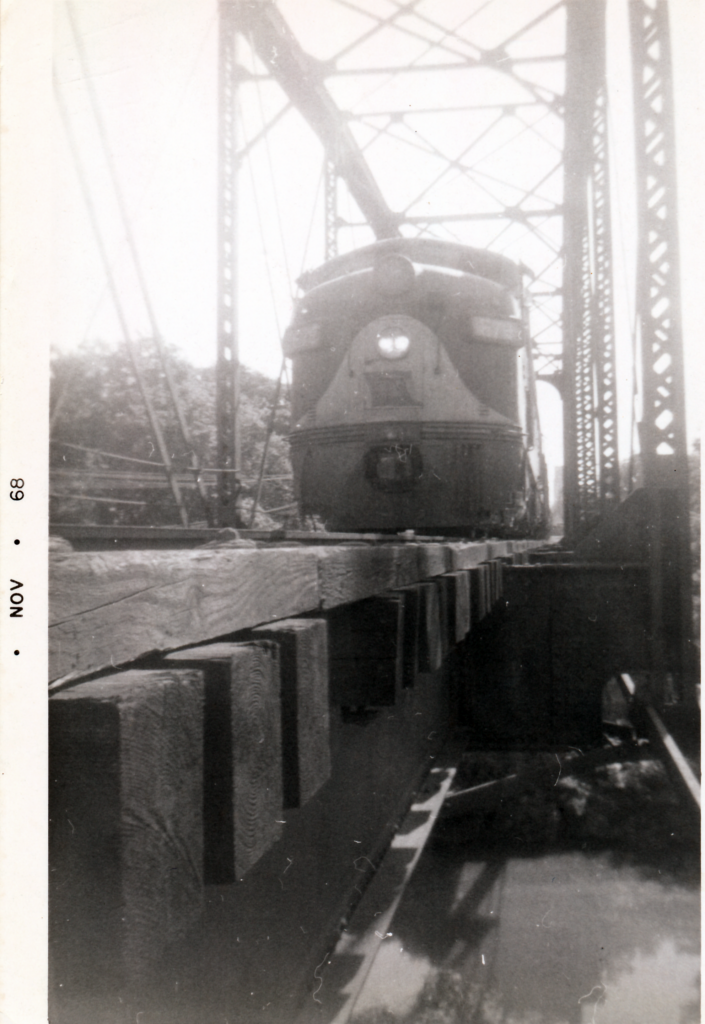

Locomotives often contained asbestos, usually in the form of pipe wrapping.

During one remediation in 1991, technicians found cloth-like wrapping around an air compressor pipe that consisted of 85-90 percent asbestos. Seven years later, during another remediation, technicians found an average of 75 linear feet of asbestos per locomotive, with one unit having 250 linear feet of asbestos material.

Remediators during the 1990s and early 2000’s found asbestos on exhaust pipes, manifold pipes, governor lines, cab heater lines and even water lines.

Asbestos was also found wherever there were steam lines, such as beneath passenger and dining cars. Rail workers whose job was to check lines beneath such cars could potentially come into contact with material from asbestos-wrapped steam lines.

Asbestos-containing materials (ACM) were also identified in rail yards, in boiler buildings and associated steam pipes as well as part of roofing materials, floor tile and even so-called “pipe mud” or caulking compound. One remediation report noted that “pipe-fitting mud” contained 2 percent amosite, a form of asbestos. An inspection report from the 1990s noted that a signal shack built in 1980 contained transite (concrete building material mixed with asbestos) wallboard consisting of 29.8 percent chrysotile.

Additionally:

- Exposure to asbestos causes a chronic, (currently) incurable disease called asbestosis which involves scarring of the lung tissue. The latency period between exposure to asbestos and onset of asbestosis can range between 10 and 40 years.

- Exposure to asbestos can also cause lung cancer.

- According to OSHA, the current maximum allowable exposure limit, 0.1 fiber (>5microns)/cc results in an excess cancer risk of 3.4 per 1,000 workers and a 20-year exposure risk of 2.3 per 1,000 workers.

- There are several kinds of asbestos, but chrysotile is most commonly used on the railroad. Some pipe wrapping materials used on the railroad are composed of both (a) chrysotile, sometimes called white asbestos, and (b) amosite, sometimes called brown asbestos.

- Chrysotile asbestos is slightly soluble in the lung and is thought to disintegrate over time. Other forms of asbestos, like amosite, are not soluble in the lung.

- Airborne asbestos can float in the air for many hours, depending on length of the fibers.